Porous Membranes and Sensor Materials

Metal-organic framework (MOF) membranes have the potential to be a key technology to fight climate change to reach the EU climate goals until 2050. Membranes allow a continuous separation of gases and are able to reduce CO2 by (a) an active separation of CO2 from waste gases and (b) by making different production cycles energy efficient (green production) through a substitution of cryogenic gas distillation columns. Membranes using MOF and COF can also tackle other challanges, such as saltwater desalination and wastewater treatment to provide clean drinking water.

Amorphous Molecular Sieving MOF Glasses

A novel class of glassy materials, so called MOF-glasses, has been derived from the discovery of meltable MOFs. Amorphization and glass transition in ZIF-62 happens upon reaching 450 °C. The crystal undergoes becomes a porous melt, and after melt-quenching shows a glass transition temperature of 330 °C. The large melting window allows to combine the world of glass science with the world of porous hybrid materials. When processed carefully, the MOF-glass has remaining porosity features of the MOF, while being a processible glass material at the same time. This allows for novel applications in gas separation and responsive sensing that have never been there in the world of MOFs and glasses, shifting paradigms both worlds.

Read more in our paper in Nature Materials and Nature Communications

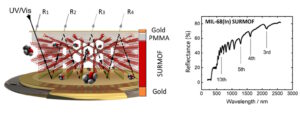

Diffusion in Stimuli Responsive Gas Separation Membranes

The synthesis of MOFs and COFs is usually approached solvothermally on a ceramic membrane support. However, it can be taken to the next level by using liquid phase epitaxy (LPE), which can produce a unit cell precision coating, even on a rough, ceramic support. This powerful technology also allows to build up hierarchical MOF membranes, combining the separation parameters of the component MOFs. To obtain a continuous gas separation tunability of MOF membrane films, which could eventually lead to performance boosts, the application of external stimuli in-situ is a novel technique. Choosing the right MOF and the correct external stimulus can result in a selectivity tuning, for example by irradiation with light, or by “defibrillation” of the lattice by electric fields leads to enhanced molecular sieving.

Read more: Our paper in Science

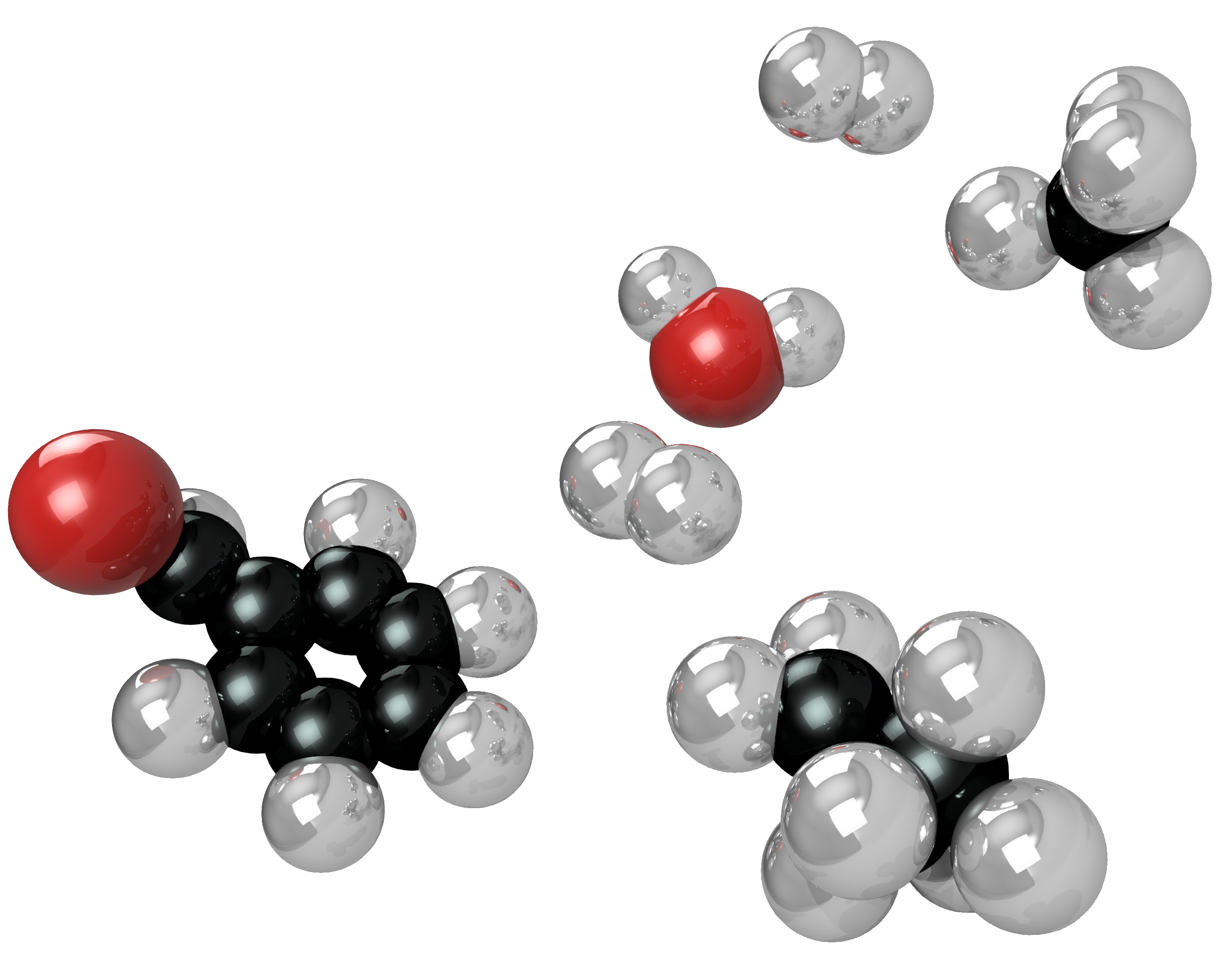

Porous Liquids and Mixed Matrix Membranes

A novel class of materials are Porous Liquids (PLs), being a colloidal MOF solution in which the solvent molecules cannot penetrate the pores of the framework. Thus, the nanocrystals remain empty in a solution. PLs can be used as processable MOF systems, that are highly monodisperse, allowing extreme high loading into gas separating polymers. MOF-fillers in polymeric matrices are called Mixed Matrix Membranes (MMMs), which are the industrially relevant types of membranes, due to their low costs and high processability.

Read more: Our Paper in Nature Materials

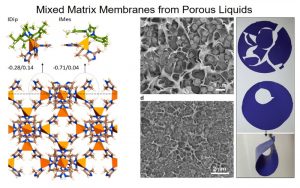

MOF Thin Films for Sensor Materials

Thin films of metal-organic frameworks can be deposited in many ways, such as electrochemical deposition, in-situ solvothermal synthesis or secondary growths, and further on many different substrates, from ceramics, to polymers to gold surfaces. If optical high quality is desired to make an optical gas sensor, flat surfaces – mainly Si-wafers and Au-mirrors – are used. The technology applied is so called “SURMOF growth”: First, a self-assembled monolayer (SAM) is grown on the desired substrate and a layer-by-layer deposition through cyclic growth is performed. In the example below, a film of MIL-68 was deposited on a gold surface, was further covered by PMMA and another gold layer was added. This led to a dimensionally confined Fabry-Pérot devices, where UV/vis irradiation is reflected several times between the layers. Further, guest molecules introduced to the MOF-thin film shift the dielectric constant of the MOF and lead to strong changes in its spectral characterization.

Read more: Our paper in ACS Nano

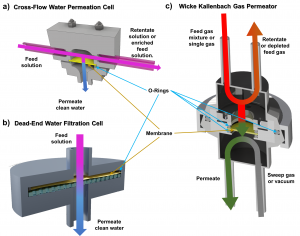

Wastewater Treatment

A great challange of today, becoming more and more important in the future, is to provide clean drinking water to the people. Therefore, wastewater treatment and desalination of seawater become more and more important. We mainly focus on wastewater treatment via molecular sieving of dye molecules from water. High flux and high separation values are important in order to achieve high performance membrane systems. Two separation techniques are of interest here, which is cross-flow continuous filtration and dead-end batch filtration. Whereas the first method is relying on molecular sieving, the latter one is relying on the adsorptive properties of the membrane (filler) material.

Read more: Our paper in Chemie Ingenieur Technik